Sumary: We can get the answer of wire nail vs concrete nail,the application of them,and how to make them.

Wire nails and concrete nails are very common in our life. They are used in many fields. However,we don’t know the difference between them, Today we will find out the answer together.

Firstly,let’s learn some knowledge about wire nails and concrete nails. It is necessary to know what they are and what they can do before we make analysis of them.

In order to make it clear,I will divide this article into three sections:What is wire nail? What is concrete nail? The application of wire nails and concrete nails

Let’s start!

Table of Contents

What is wire nail?

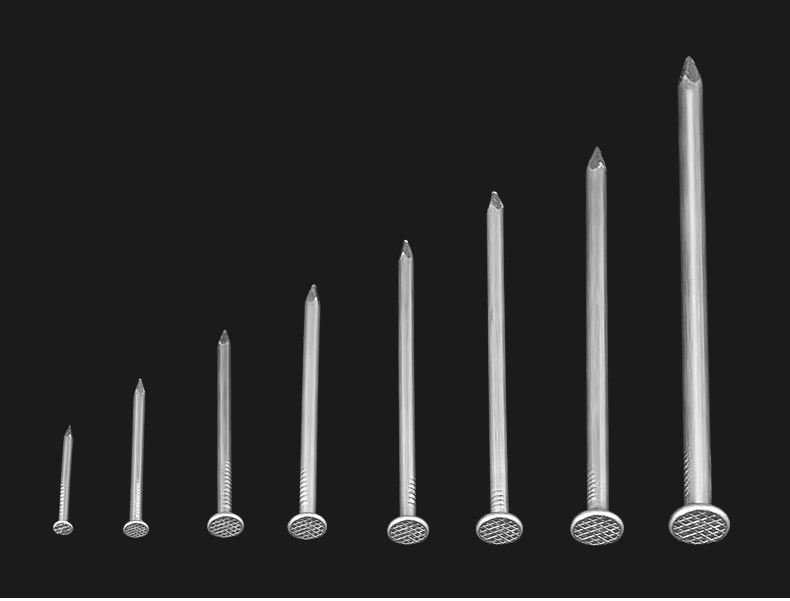

The wire nail is made of a low-carbon steel wire rod. It also can be called common round nails. The wire nail is one of the most common and commonly used nails, which is widely used in construction, furniture and other industries.

What is concrete nail?

The concrete nail is a kind of cement nail. The shank of the concrete nail is mostly round and has a certain degree of torsion. The main function of the torsion on the shank is to increase friction with the cement wall during use, so that the cement nail can be firmly fixed in the cement wall.

The application of wire nails and concrete nails:

The application of wire nails and concrete nails is also different,wire nails are mainly used in softwood and other wooden structures. These wooden structures include doors and windows, furniture accessories, packaging boxes, etc., and we can see that it is more suitable to use concrete nails in hardwood because it has strong hardness and toughness, while in softwood we think that wire nails are more suitable because they have stronger bending resistance than concrete nails.

Wire nails application:

Wire nail is a very common type of fastener with a wide range of applications. It can be applied in wooden board, furniture production industry and building construction industry, packing box, wooden furniture and so on.

Wire nails are the most commonly used and most versatile of all fastener types. They have a smooth shank,a diamond point and a large flat head. Their length is measured from the point to the underside of the head. The diameter is measured from under the head.

Concrete nails are short, heavy-duty fasteners that are driven into concrete or masonry with a hammer. To prevent rusting, concrete nails are coated with rubber or an aluminum alloy.

Wire nails are made of low carbon steel wire rods,quenching treatment for their surface,and then be cut into nail shape.

Concrete nails are made of low carbon steel wire rods,quenching treatment for their surface and pointed by high temperature heat treatment.

Concrete nails can be used in wall mounting picture frames, hanging curtain rods and other light objects that do not require a lot of strength.

How to make wire nails and concrete nails

To make wire nails,we should use cold heading process firstly ,then nail cutting machine to process the nail shank and head and nail point. Finally we should use polishing machine to polish them to get the nails bright and shinny.

To make concrete nail ,we should use cold heading process firstly ,then qu

How to make concrete nails?

- Wire drawing machine: High carbon steel wire drawing from 6.5mm to 4mm or 3mm etc.

- Nail cutting machine: Make the steel wire into nails.

- Belt type furnace: Heat treatment to make the nails strong.

- Galvanizing Equipment: to make the nails anti-corrosive.

We need to choose the best raw materials on the basis of ensuring the quality of products. The raw material for making concrete nail is high carbon steel wire SAE1045- SAE1060 with a diameter of 6mm~6.5mm for the first drawing; a diameter of 3~4mm for the second drawing; After get the needed diameter, then can make concrete nails by the concrete nail making machine.

Step 1:

To make concrete nails, it also needs belt type furnace, in the furnace, it finish two process:

Go through a process called quenching first. This is where the nail is heated to about 800-1,000° Celsius and then immediately cooled in oil. This technique causes the steel of the nail to become extremely hard and strong, but it also makes it more likely to break if it’s bent too much or otherwise stressed. The best way to quench concrete nails is by heating them up until they’re red hot and then submerging them in oil while they’re still glowing.

This quenching process makes them incredibly hard, but also makes them susceptible to breaking (which is why they are brittle).

Step 2:

Annealing in the second section of the belt type furnace:

After annealing, the concrete nails will not be brittle and break easily anymore.

wire nails vs concrete nails

When it comes to the wire nails vs concrete nails, you may know them. But do you know their differences and similarities?

A wire nail is smaller in diameter than a concrete nail. The shank of a wire nail is smooth, while the shank of a concrete nail has rings or ridges. Wire nails are often used in light carpentry, such as building shelves and cabinets, while concrete nails are utilized for heavier carpentry projects, such as constructing decks or framing walls.

Wire nail is a solid iron rod with sharp point. Concrete nail is short and thick, but very strong, even it is incompliant with standard specification of building material code of China. Wire nail is easier to break than concrete nail.

wire nails vs concrete nails in size:

For wire nails, the length are usually from 1-6 inch (25-150mm), diameter 2.0mm, 3.0mm, 4.5mm, 5.5mm

For concrete nails, the length are usually from 1-4 inch (25-100mm), diameter 3.0mm, 4.0mm, 5.0mm