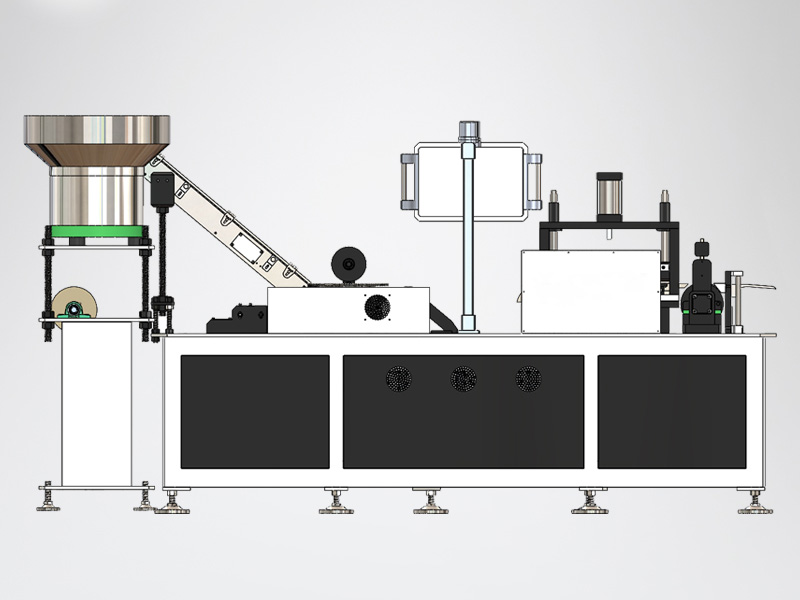

Collated Screw Assembly Machine

Collated Screw Assembly Machine Automatic Screw Assembly Machine Drywall Screw Collating Machine This machine adopts servo drive, PCL control, human-machine interface interaction, which effectively improves assembly accuracy and assembly speed (up to 800 screws per minute, about 16 multi-chain screws)

Collated Screw Assembly Machine Introduction

The collated drywall screw assembly machine, the function is to assemble the drywall screws into collated coils or plastic belts.This machine adopts the servo drive, PLC control, and human-machine interface interaction by touch screen, which effectively improves the assembly accuracy and assembly speed (the highest speed can assemble 800 – 1000 pcs screw nails per minute, which is about 16.5 chains). The machine interface interaction makes the operation easier and easier to use.

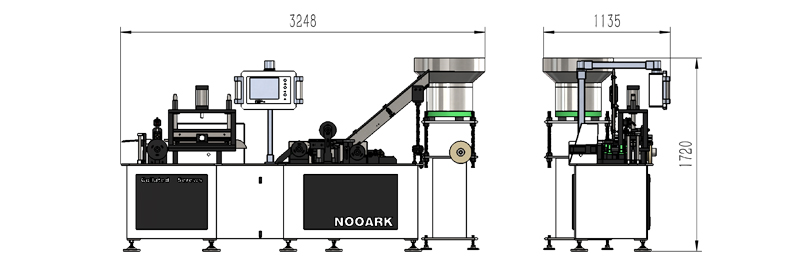

Parameters of the Collated Screw Assembly Machine

- Model: NCS-CYDX

- Diemension: 3248x1135x1720 mm (length x width x height)

- Voltage: 220V Single phase 220V

- Frequency:50/60Hz (optional)

- Power: 5.5KW

- Working speed up to 800-1000 pcs/min (adjustable)

- Assembly range: Diameter 3.5mm, Length: 25-55mm (other wire diameters can be customized)

- Air pressure: 1.0Mpa

Mechanical characteristics:

- Electrical part: The main electrical components are composed of high-quality brands such as Delta, Omron, Schneider etc., which ensure the efficient, stable and precise electrical control of the chain belt drywall screw assembly machine (press belt type and Injection molding belt type).

- Mechanical components: The main mechanical components are processed by CNC machining centers to ensure the quality and accuracy of mechanical components, and achieve efficient, stable and precise operation.

- Pneumatic parts: The pneumatic original parts adopt domestic well-known brand SNS Shenchi products to ensure the stable and durable operation of the pneumatic parts.

- Vibration plate: The vibration plate adopts Zhentai brand products, which guarantees high-speed and stable drywall nail feeding link operation.

- Detection device:

-

- Slideway detection It is used to detect whether the nail material in the slideway is lack of material, and it will automatically stop and alarm after lack of material.

- Material belt detection: It is used to detect whether the material belt is lack of material, and it will automatically stop and alarm after lack of material.

- Long material detection: It is used to detect whether there is over-long nail material in the distribution tray, and the side automatic shutdown alarm.

- Stamping height detection is used to adjust the pause position of the pressing plate.

-

- Upgrade and update: The software and hardware of this machine have been individually designed by our company. The upgrade of software and hardware and the realization of special control in a certain link can quickly provide solutions.

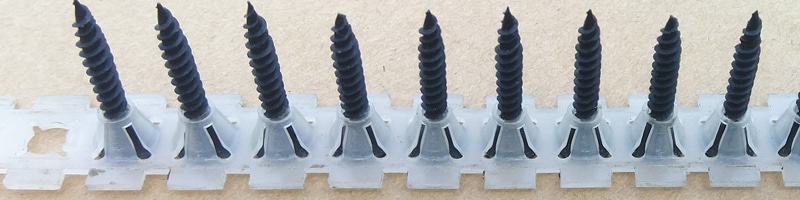

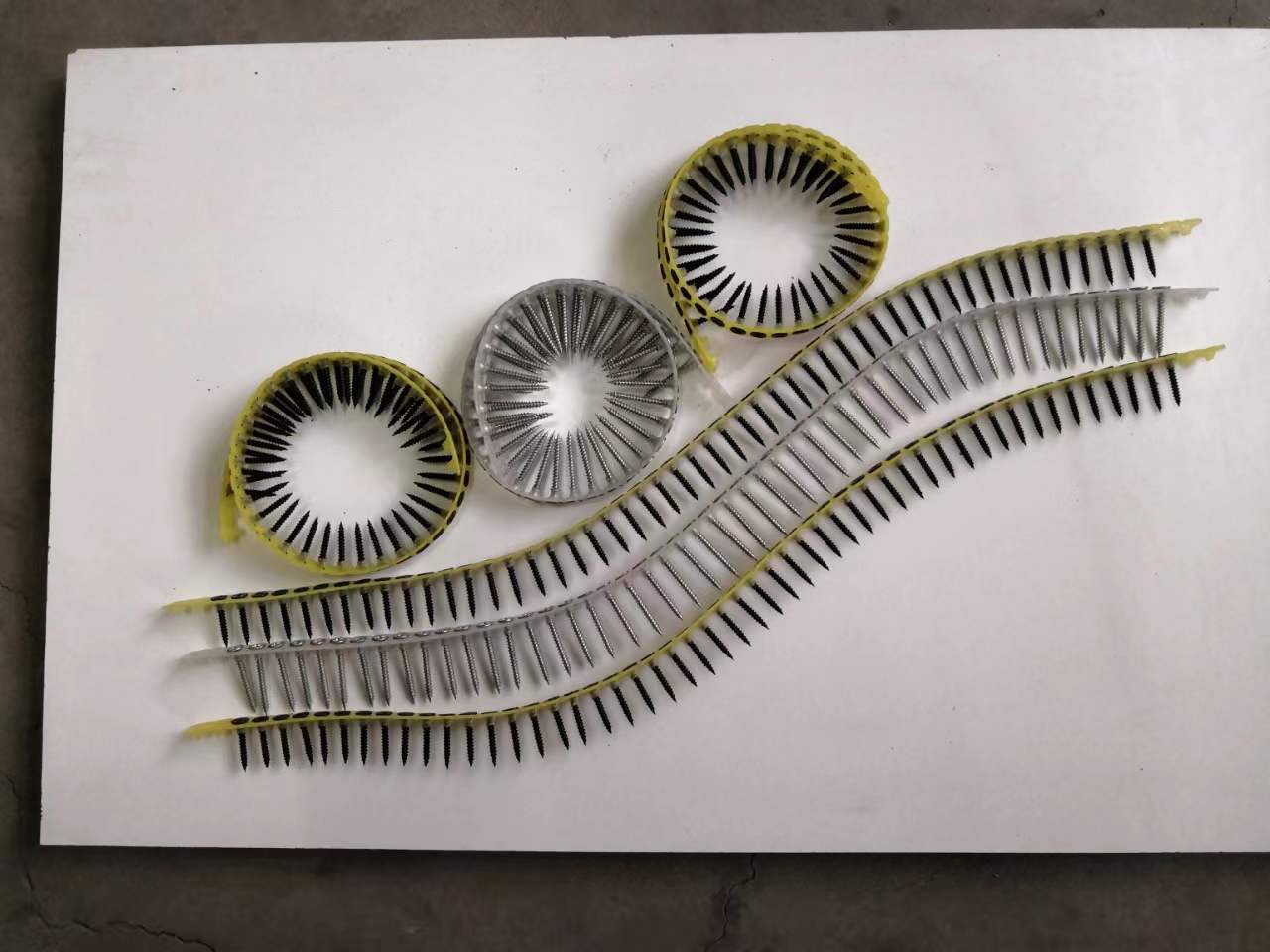

Collated Drywall Screw Pictures:

How the Collated Screws are Made?

1. Manual feeding:

- After completing the operation in the previous section, click “Split continuous operation”. When about 5 chain belt drywall screws are assembled for the preliminary assembly, click “Split continuous operation” again to stop the preliminary assembly operation.

- Click “Cut Positioning”, after the cutting and positioning chain is searched to the positioning detection point and stop, manually pass the preliminarily assembled chain belt drywall nails from the entrance of the punching mechanism’s trough to the punching mechanism.

2. Stamping and cutting operation:

- After the preliminarily assembled chain belt drywall screws are sent into the punching mechanism, click “manual punching” once, and the punching mechanism will operate to completely press the drywall nails into the holding holes of the chain belt.

- After completing a “manual stamping”, continue to manually send the chain belt to the cutting mechanism, and align the cutting position of the chain belt with the cutter position of the cutting mechanism.

- Click once on “Manual Cut”, the cutting mechanism will operate, and the cutter will cut the chain.

3. Adjustments:

- Adjustment of the suspension position of the pressure plate: The suspension position of the pressure plate needs to press the cap of the dry wall screw. If the pressure plate does not press the screw cap or presses in too much when the pressure plate travels down to the pause, the position of the material height detection switch needs to be adjusted; Click once on “Press Plate Positioning” to move the press plate down and keep it in the down pause position. Observe the position of the press plate and the nail cap. If it is not pressed, the material height detection switch needs to be lowered, and the material height detection switch needs to be raised if it is pressed too much.

- Adjust the clamping force of the splint: right the splint of the drywall screw. When the clamping force is too large, click the pressure adjustment minus button, and if the clamping force is too small, click the plus button.

- The cutting position is not in the center: Loosen the fixing screws on both sides of the cutting and positioning chainring, and rotate the two chainrings to adjust the alignment.

4. Conclusion: After the operations in this chapter are completed, the basic operation of the chain belt drywall nail assembly is completed. Click the “automatic mode” button to switch to the automatic mode, click the “start” button, and the equipment will start automated assembly and production operations.