Coil Nail Making Machine

The coil nail welding machine,designed for making coil nails from 25-130 mm ,it can weld ring shank ,screw shank or smooth nails into coil nails.

Table of Contents

Automatic coil nail making machine video:

What is Coil nail making machine?

Coil nail making machine is also called coil nail collator, it is designed to make coil nails and it welds screw/ring shank nails into nail coils automatically. The machine speed can reach max 3000 pcs/min with an average power consumption of 5kw.

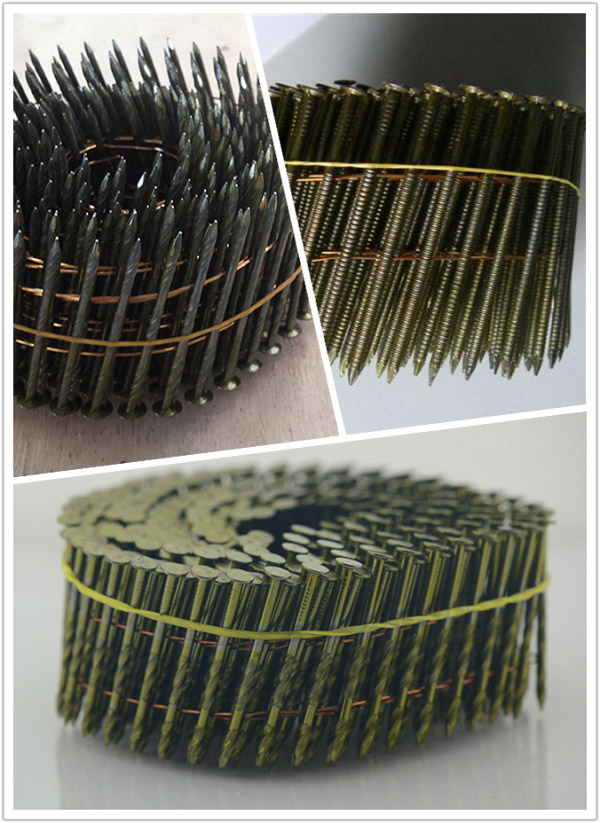

What is coil nails?

The coil nails are usually 15 or 16 degree and are used in coil nail gun. The coil nail is composed of a certain quantity of same shape nails with same distance, connected by copper plated steel wire ,the connecting wire is in a direction of β angle with respect to the center line of each nail, then rolled in coil or bulks. Coil nails can save efforts and improve productivity greatly.

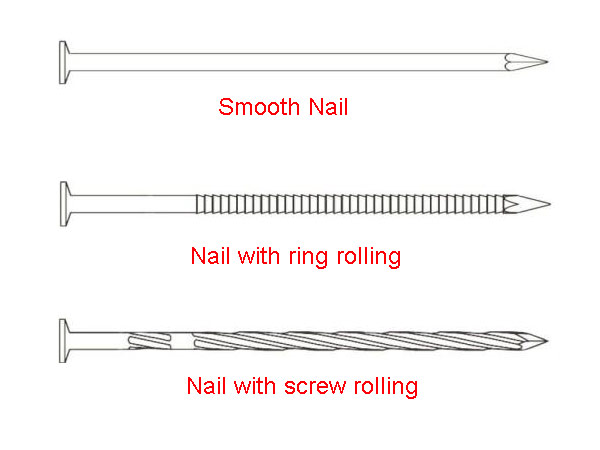

Coil nails drawing :

Working Process of Coil Nail Making Machinie :

Making wire nails first ,after getting wire nails ,use the nail thread rolling machine to get different kind of threaded nails ,ring shape or screw shape etc ,after this ,put these nails into the Vibration plate so that they will be feed into the coil nail making machine and be welded into coils .

The common used coil nails specifications in China and other countries such as Mexico ,Uzbekistan,USA, Brazil,India,Saudi Arabia, UAE , Vietnam etc are :

Length :38 mm ,diameter :2.1 mmLength :50 mm ,diameter :2.3 mm

Length :64 mm ,diameter :2.5/2.8 mm

Length :75/80 mm ,diameter :2.8/3.0 mm

Remarks :we can customize the moulds for different size of nails .

This is a video of the coil nail making machine working in our Chinese customer factory , you can see in the video of the welding speed 2300 pcs/min.

Advantages:

Automatically rubber banding: the process of manually putting the rubber bands is removed, The coil nails are automatically welded and put on with rubber bands, then transferred to the platform automatically. Compared with the nail collating machine without auto rubber banding system, of which it needs a worker to catch the finished coil nails in time, in case it falls to ground and break its shape. This way it greatly reduced the work intensity of workers and the requirements for workers’ skills and proficiency, and improves production efficiency.

The nail hold platform can store about 60 finished nail coils, and the direction can be changed.

The new patented coil nail cutting technology,the cutting failure probability is less than 1/10 of that of ordinary machine model, this can greatly reduce the occurrence of waste coil nails.

Improve automatic operation:

- Automatic shutdown if the coil is cut off or welding wire is broken.

- Stop when finish nail coils are not cut off.

- Stop when the rubber band is used up.

- Perfect protection, the touch screen will display the fault reason

Equipped with: 850mm diameter vibrating bowl, self-weight of the vibrating bowl 380KG, double electromagnets with 6 sets 15-degree vibrating plates,

The larger diameter, the faster speed machine can run, the smaller nail beating amplitude, this way it can work stable for long time and can be used for big nails .

Equipped with Our patent product high frequency nail welding machine.

Equipped with: Omron PLC, WEINVIEW touch screen, can adjust the working parameters directly on the screen, and it shows the detailed reason which cause the machine stop.

Features of Automatic Coil Nail Making Machine:

- The newly developed welding seat mechanism eliminates the need to adjust the height of the welding seat, then it will reduce the coil nail welding waste, and also reduces the technical requirements for welding adjustment.

- The finished product platform stores more finished products and is more practical. It can hold 60 rolls of finished coil nails.

- All parameter settings can be completed with only a 10-inch touch screen

- Compact machine, reducing floor space

- The mechanical structure and pneumatic control are simpler, convenient to adjust, and reduce the failure rate.

Automatic coil nail making machine testing video:

Parameters of the automatic coil nail making machine:

2. Straight steep down rail: 1,400 mm length, 30° adjustment of alighment

3. High frequency inverter welder:2000A-3000A, 7V.

4. Coiler: flat, and roofing type coiling (conical coil)

5. Auto rubber band system available – yes.

6. Carrier armed touch screen computer control.

7. Power: 380-415 V, 3-phase, 50 Hz, estimated consumption about 5kw.

8. Air consumption –6 bar, 0.6 m3/min.

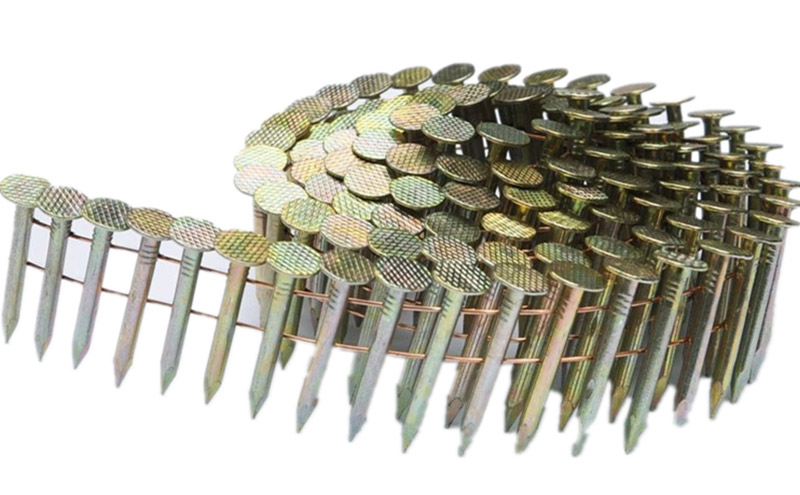

Detailed pictures of the welding point of the Collated Coil Nail:

Different kind of Coil nails made from the nail collator machine (smooth nail body ,ring type nail body ,screw type nail body):

FAQ:

-

What’s the max length of the coil nails this JD-100 nail collator can weld?

This nail collator can weld 25-100mm coil nails with max speed 3000 pcs/min, the smaller the nails, the higher welding speed.

-

What’s the welding speed for different size coil nails?

For Diameter: 2.0-2.1mm, Length: 32-38mm, Speed around 3000 pcs/min.

For Diameter: 2.3-2.5mm, Length: 50-60mm, Speed around 2600 pcs/min.

F0r Diameter: 2.8-3.1mm, Length: 70-80mm, Speed around 2200-2400 pcs/min.

For Diameter: 3.3 mm, Length: 80mm. Speed around 1600-1800 pcs/min.

-

How to select the suitable size of coil nail Collator mould (welding gear)?

When selecting the mould for coil nail welding machine,there are 3 parameters to consider:

1,How many grooves are in a circle of the mold (related to the length):

There are 3 numbers of grooves for the moulds:

75 grooves for 100mm and longer nails.

94 grooves for 45-100 mm nails.

115 grooves for 25-38 mm nails.

2, The diameter of the nail:

Nail diameter: plus or minus 10% of the applicable range, for example, the mold of 2.1 mm can also work for diameter of 2.0, 2.2mm.

3, The thickness of the mold:

The thickness of the mold:When the nail length is bigger than 80mm coil nail welding machine mould thickness is 60mm, and when the nail length less than 80mm then the mould thickness is 45mm.

Common used models of the nail collator mould(welding gear):

115 grooves, wire diameter 2.0mm (make length of 25-38 mm coil nails, diameter of 1.9-2.1mm)

94 grooves, wire diameter 2.3mm (make length of 45-75 mm coil nails, diameter of 2.1-2.5 mm)

94 grooves, wire diameter 2.8mm (make length of 45-100 mm nails, diameter of 2.6-3.0 mm)

The application of coil nails :

Coil nails can be used in many places such as construction ,assembly of various wooden container (pallets ,europallets,wooden boxes ,furniture,etc).

Coil Nail Collator and copper coated welding wire loading pictures:

Nail Collating Machine for Big Flat Head Clout Nails:

Big Flat Head Clout Nails size :

Diameter: 3.05mm, Length: 25mm/32mm/38mm, nail head 10 mm.

Related products

1,Nail gun

2,Copper coated wire for coil nail making

3,Quick dry paint

4,Coil nails